I built a filament dehydrator following the basic plan on Taulman3D’s site, which I expect to need for both PETG and nylon prints. PLA prints have never been a problem for me here in the high desert.

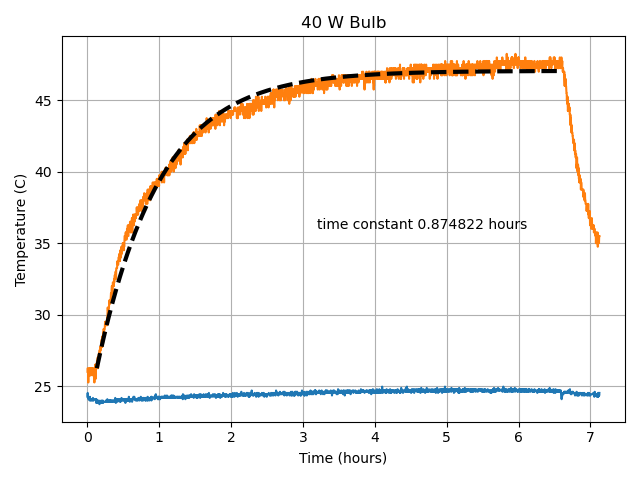

Taulman3D suggests using a 40 W or 60 W lightbulb as the heat source, and that the 40 W bulb will reach full temperature of about 110F. I used a 40W bulb and instrumented my bucket with my thermal data logger tracking temperature both in the ambient garage and in the center of the filament spool.

I estimate my steady state temperature at about 48C (118F) in a still room at 25C (77F). I fitted the rising part of the curve to an exponential model, and estimate the time constant at about 0.87 hours (52 min). Steady state can be assumed within about two to three time constants or about 2 hours.

The relevant filament types that I work with have recommended drying times and temperatures (according to my eyeball averaging of Fillamentum, 3DXTech, 3devo) of

- PLA 40-50 C, 4-6 hours

- ABS 65-75 C, 4-6 hours

- PETG 60-65 C, 4-6 hours

- Nylon 75-90 C, 4-6 hours

My dryer is probably good for nylon, though I would run it longer, fine for ABS. It is too hot for PETG or PLA, though I believe that can be fixed with lower wattage lightbulb, gapped lid, or source modulation. I have a PID controller around here somewhere…